Protecting Business Assets: How to Easily Maintain Diesel Engines

If your company has diesel engines, you must learn how to maintain them. If you don’t, they will break down and require more extensive and costly repairs. You’ll all waste money, time, and effort, and your resources and reputation will suffer.

But how can you go about regularly maintaining diesel engines? More importantly, what can you do to protect them successfully and efficiently?

Luckily, reading up on diesel maintenance tips is simple and easy. Below, we document the absolute best advice for learning how to successfully maintain diesel engines in all types of weather and situations. Keep reading to learn more!

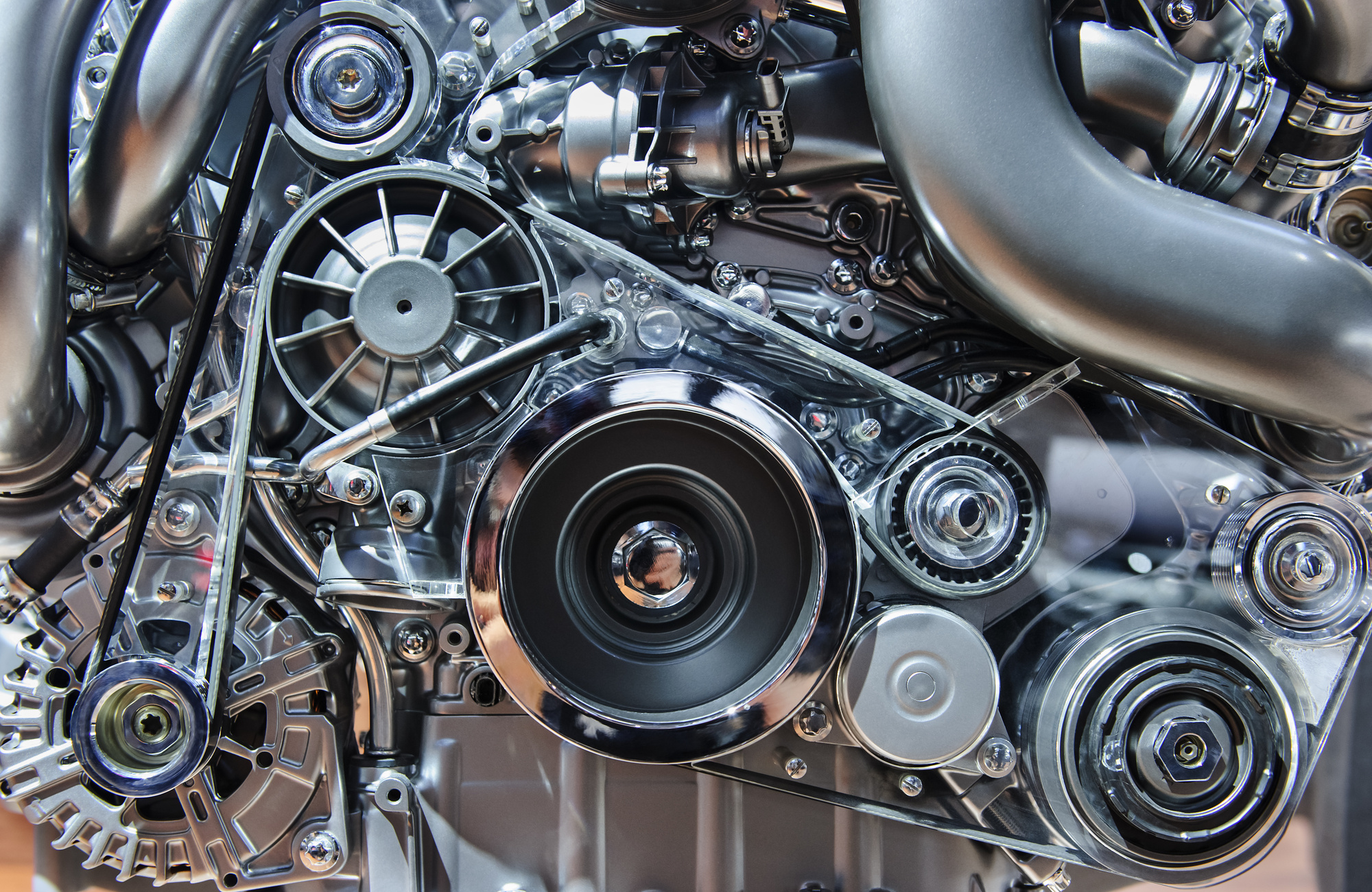

Identify the Elements of a Dependable Diesel Engine

Protecting business assets requires regular maintenance. It ensures the diesel engine remains in good condition.

The most critical elements of a dependable diesel engine are air intake systems, fuel delivery systems, cooling systems, lubrication systems, exhaust systems, and the engine itself.

Inspect air intake systems to ensure they are functioning. They will deliver enough clean air at the right speed. Check fuel delivery systems to ensure they bring fuel at the correct pressure to the correct cylinder. Inspect cooling systems to ensure they are working.

They deliver the right amount of coolant to the engine. Inspect lubrication systems to ensure they provide the proper amount of oil to the engine. Check exhaust systems to ensure they are running. It reduces the levels of smog and other pollutants.

Get to Know Common Causes of Failure

Maintaining diesel engines is essential in protecting business assets. You can cost-effectively do this by knowing and understanding the common causes of failure.

One of the most frequent causes of engine failure is an engine blowby. The question is, what is engine blowby?

Engine blowby is a condition in which some of the exhaust gases escape through the seals or rings of the pistons. It causes them to enter into the crankcase of the engine and create a pressure differential.

The presence of these gases and byproducts can make an over-pressurized crankcase. It promotes an environment that is conducive to abrasion and injury.

Over time, blowby can cause the buildup of sludge and debris. It can clog the internal workings of the motor and cause failure.

Checking and servicing an engine is vital. It can ensure that their assets remain protected and in optimal condition.

Leverage Technology to Check and Diagnose Issues in Early

Modern technological advances have made it easier to check and diagnose issues with diesel engines. It includes cylinder heads, heat exchangers, and filters.

Using sophisticated monitoring tools, such as inspection cameras, and other diagnostic equipment, technicians identify and address any problems. It is before they become more costly in the future.

Integrate routine maintenance and periodic inspections of the diesel engine. It alerts technicians of any abnormalities. It prevents long-term failure or damage to business assets.

Keep the diesel engine running. It protects the business’s bottom line and also its reputation.

Using the latest technology to detect and address issues can help maintain reliable diesel engines. It results in happy customers and fewer risks associated with financial losses.

Check Diesel Engines To Protect Business Assets

All in all, maintaining diesel engines is an essential part of ensuring your business assets are kept safe. Though the process may seem complicated, simple steps like changing oil, testing fuel, and inspecting the air filter can make the job easier.

Check with your manufacturer for best practices and knowledge to keep your business machines running smoothly!

Did you find this article helpful? Follow this link to read more automotive content.